Internal grinding wheels offer precise grinding of internal surfaces to obtain excellent surface finishes with accurate dimensioning. They are further engineered to reduce dressing frequency and improve stock removal rates. In contrast to cylindrical surface grinding, internal surfaces require high wheel-work conformity implying that the pre-dressing of the wheel surface be exact. Internal grinding wheels find a range of applications in the grinding of gears, bearings, inner rings, outer rings, steering nuts etc. Some of the industries that use these wheels are.

1. Engineering component manufacturers

2. Cutting tools

3. Tools and dies

4. Bearings

5. Auto ancillaries

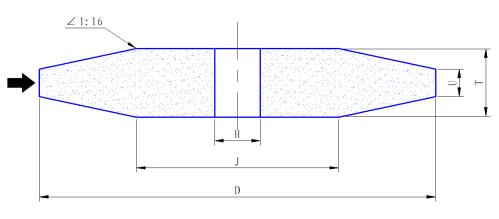

Type Code: 4

|

OD |

T |

H |

U |

Grit |

Grain |

Hardness |

Structure |

Speed |

|

125mm |

13mm 16mm 20mm |

20mm 31.75mm 32mm |

4mm 6mm |

A WA AA 38A 25A PA SA GC |

F60 F80 F100 F120 |

K L M N P Q |

5 6 7 8 9 |

35m/s 40m/s 45m/s 50m/s |

|

150mm |

16mm 20mm |

|||||||

|

200mm |

13mm 16mm |

75mm |

||||||

|

250mm |

10mm-25mm |

11mm |

||||||

|

300mm |

20mm 25mm |

6mm |

||||||

|

32mm |

127mm |

|||||||

|

350mm |

32mm |

|||||||

|

400mm |

32mm |

|||||||

|

455mm |

32mm-90mm |

-

Aluminum Oxide Tool Room Grinding Wheels

-

free-foundation concrete batching plant

-

Cylindrical Grinding Wheel Of Abrasive Grinding...

-

QTZ100 Series

-

Vitrified Tapered One Side Grinding Wheels For ...

-

Bench Grinder Grinding Wheel For Metal