Factory made hot-sale 100mm Flap Discs - Polishing Grinding Stone Wheel For Bench Grinders – YUXINGAN Detail:

Main Description

| Cut off Wheels For Stainless steel | Green Cut off Wheels For Stainless steel | Cut off Wheels For Steel and Metal | Cut off Wheels For Stone | |

| Features | 1. Special grain combination 2. Advanced bond system 3. Reinforced |

1. Special grain combination 2. Advanced bond system 3. Reinforced |

1. Special grain combination 2. Advanced bond system 3. Reinforced |

1. Special grain combination 2. Advanced bond system 3. Reinforced |

| Benefits | 1. Fast cut 2. Cool cut, Up to 3X life versus aluminum oxide wheels on stainless steel, Carbonsteel, cast iron. 3. Germany MPA safety standard |

1. Fast cut 2. Cool cut 3. Germany MPA safety standard |

1. Fast cut 2. Cool cut 3. Germany MPA safety standard |

1. Fast cut. Ideal for grinding stones, wood, copper. Long lastinglife |

Notice

Do not use cracked or other adverse grinding wheel.

Cutting machine must be equipped with a steel plate shield, should be able to ensure that when the grinding wheel to block debris when broken.

When in use, should make Mars down as well when horizontal cutting measures to prevent harm to other staff.

When cutting, after cutting items must be clamped before beginning work.

Product Demensions

| Order No. | Size(mm) | Inch | Pcs/ctn(PCS) | G.W.(kg) | Meas(cm) | Max.speed |

| YXG-27A1004 | 100×4×16 | 4″×4/25″×5/8″ | 200 | 21 | 38×22×22 | 80M/S |

| YXG-27A1006 | 100×6×16 | 4″×1/4″×5/8″ | 200 | 21 | 38×22×22 | |

| YXG-27A1156 | 115×6×22 | 4.5″×1/4″×7/8″ | 100 | 16 | 25×21×25 | |

| YXG-27A1256 | 125×6×22 | 5″×1/4″×7/8″ | 100 | 17 | 27×21×27 | |

| YXG-27A1506 | 150×6×22 | 6″×1/4″×7/8″ | 100 | 23 | 42×31×16 | |

| YXG-27A1806 | 180×6×22 | 7″×1/4″×7/8″ | 60 | 21 | 38×24×19 | |

| YXG-27A2306 | 230×6×22 | 9″×1/4″×7/8″ | 30 | 20 | 26×25×25 |

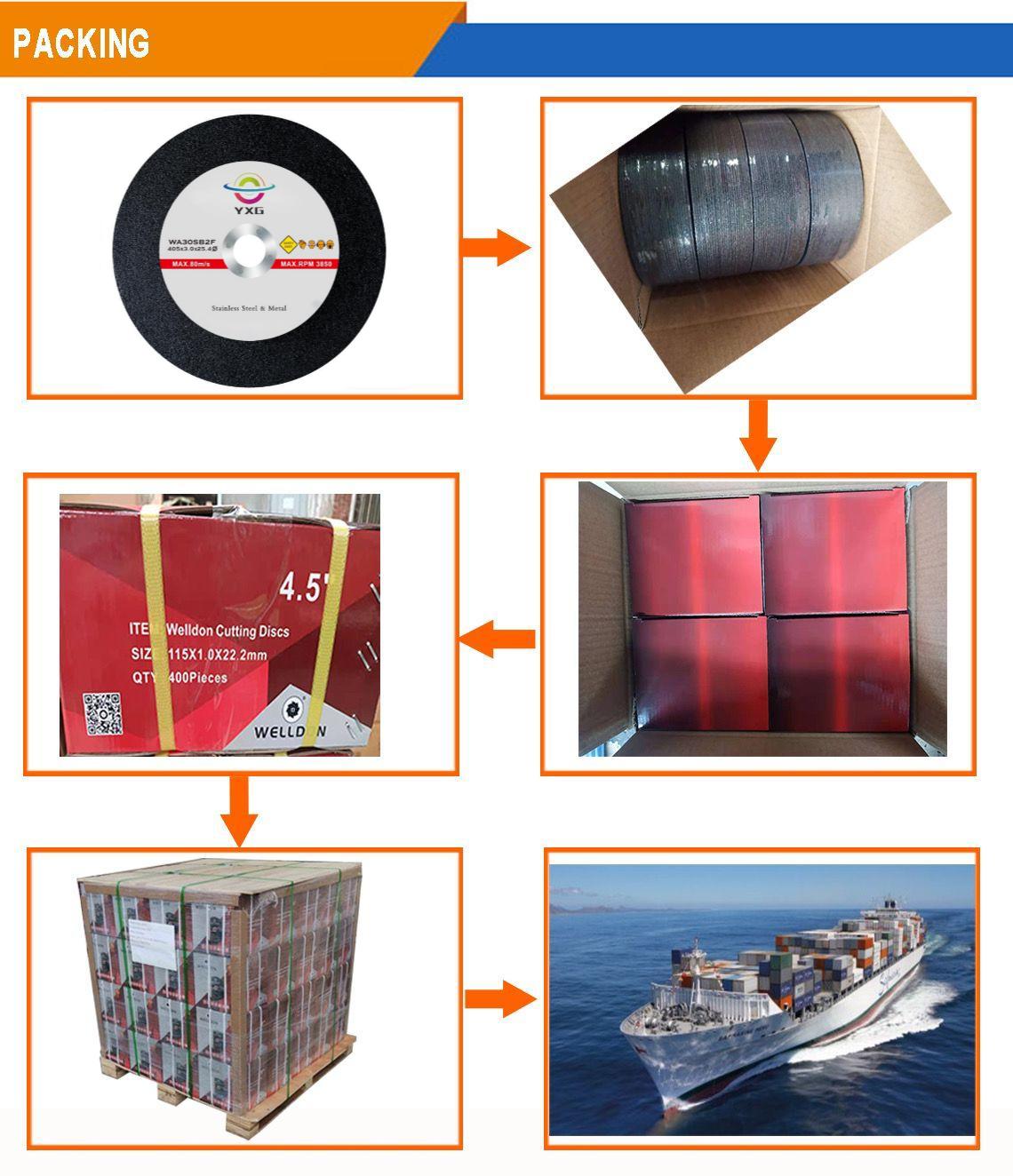

Packing And Shipping

Colorful packing: We support ODM&OEM.

Regular paper packing: We supply the paper box

Standard packing or as customer requirest

Why Choose Us

1. With more than 30 years of experience in manufacturing abrasive production lines, we understand abrasives, and we understand the past and future of abrasives. Willing to share our knowledge with our customers. Our senior technical engineers have 25 years of experience in abrasive production lines.

2. Strict quality management. We have ISO 9001.

More than 90% of our workers have worked here for more than 10 years.

3. Very honest company. The final product quality will be 100% the same as the sample. We never lower the quality or hide information for our customers.

4. Professional sales team. Our sales staff is very knowledgeable about abrasives.

They have 10 to 15 years of abrasive sales experience. Our sales are very stable and we like to work in our company for a long time. When you communicate with us, you will feel good. Most Chinese companies have less than 2 years of sales experience and lack professional knowledge. They always say “I need to ask our engineers…”

It is difficult for you to get a direct answer in time.

1. Strongly support our customers. Always provide preferential prices and quality services.

2. Supports very small trial orders and mixed orders

Thank you for reading. This is just the beginning of our cooperation.

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Excellent, Reasonable Rate and Efficient Service" for Factory made hot-sale 100mm Flap Discs - Polishing Grinding Stone Wheel For Bench Grinders – YUXINGAN, The product will supply to all over the world, such as: Honduras, Amsterdam, Southampton, With the aim of "compete with good quality and develop with creativity" and the service principle of "take customers' demand as orientation", we will earnestly provide qualified products and good service for domestic and international customers.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.

-

Cheap PriceList for Angle Grinder Cutoff Wheel ...

-

High reputation Cut Off Wheel - Alumina White ...

-

Best Price for Polish Tools - Flat Roll Resin ...

-

High reputation Abrasive Polishing Disc - Grin...

-

Low MOQ for Bench Grinder Grinding - Abrasive ...

-

Single Cage Construction Elevator - Fast deliv...