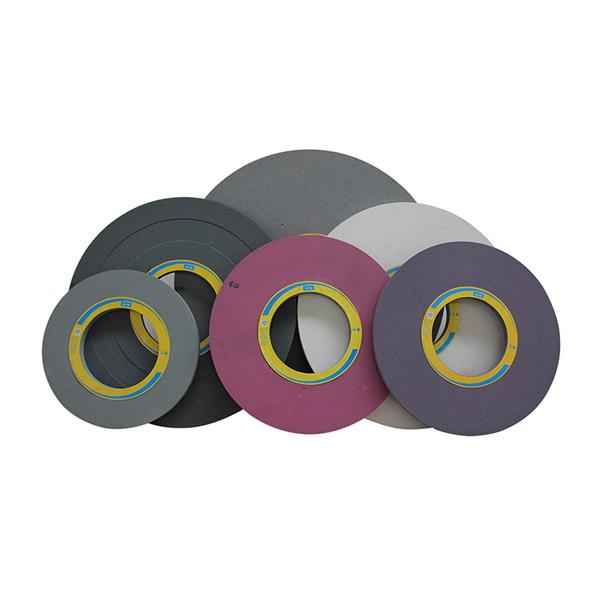

High Quality for Abrasive Cut Off Wheel - Crankshaft Grinding Wheel Vitrified Bonded Grinding Wheel – YUXINGAN Detail:

Scope Of Production

Specification: V-P-750×75×305 – PA/WA -F60-N-60m/s

Specification: V-P-900×35×305 – PA/WA -F60-M-60m/s

Specification: V-P-1065×34×305-PA/WA-F60-M-60m/s

Applicable Fields

Crankshaft grinding wheel is mainly used for automobile, ship, tractor, motorcycle engine and mining machinery. Diesel engine and other crankshaft, camshaft grinding process. Grinding all kinds of crankshafts and connecting rods.

Characteristics Of Grinding Wheel

The static balance of the series of grinding wheel in our company is superior to the national standard 30~50%, and it has good selfsharpness and good maintenance of fillet, long life.The static balance of the set of grinding shaft and camshaft grinding wheel are 50%better then the national standard. The thickness deviation of the grinding wheel is less than 0.2mm and the parallel ity is less than 0.1mm. Excellent geometric accuracy; Good grinding performance; Excellent hardness stability; Excellent R-angle holding and less chances of burn;

The wheels are mainly used for grinding all kinds of crankshafts and camshafts of auto,tractor motorcycle, ship engine as well as transport machinery etc. Our wheels have uniform Structure and hardness. out of balance performance, and cost performance etc.

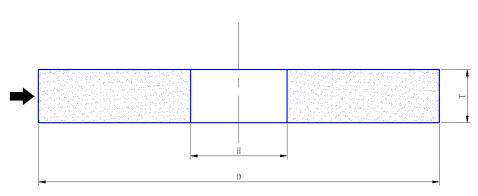

Type Code

|

OD |

T |

H |

Grit |

Grain |

Hardness |

Structure |

Speed |

|

500mm |

16mm 18mm 19mm 20mm 22mm 25mm 32mm 38mm 40mm 50mm 63mm 90mm 120mm |

127mm 203mm 203.2mm 304.8mm 305mm |

A WA AA 38A 25A PA SA GC C |

F36 F46 F54 F60 F80 F100 F120 |

K L M N P Q |

5 6 7 8 9 10 |

33m/s 35m/s 40m/s 45m/s 50m/s 60m/s |

|

600mm |

|||||||

|

610mm |

|||||||

|

635mm |

|||||||

|

660mm |

|||||||

|

700mm |

|||||||

|

710mm |

|||||||

|

750mm |

|||||||

|

760mm |

|||||||

|

810mm |

|||||||

|

900mm |

|||||||

|

1065mm |

|||||||

|

1100mm |

Resin Bond Wheels

Resion bond is usually made with heat-cured resin mainly composed of phenolic resib Resin bond wheel has excellent grinding ability, surface finish and minimal chipping. It is widely applied for difficult- to-machine materials such as cemented carbide, ceramics, glass,and silicon as well as ferroous materials such as high-speed steels and sintered ferrous metals.

Vitrified Bond Wheels

Vitrified bond is a vitreous binding material and generally contains pores inside while other materials contain no pores. Therefore vitrified bond wheels have excellent grinding ability and are superior in forming.

Product detail pictures:

Related Product Guide:

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for High Quality for Abrasive Cut Off Wheel - Crankshaft Grinding Wheel Vitrified Bonded Grinding Wheel – YUXINGAN, The product will supply to all over the world, such as: Israel, Ethiopia, Hungary, We strive for excellence, constant improvement and innovation, is committed to make us the "customer trust" and the "first choice of engineering machinery accessories brand" suppliers. Choose us, sharing a win-win situation!

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

-

Factory Free sample Flap Tooling Cutting And Gr...

-

Factory Price For Stone Grinding Tool - Alumin...

-

OEM Factory for China Disc Abrasives - Grindin...

-

Wholesale Price 150mm Cutting Discs - Metal An...

-

Manufacturing Companies for China Grinding Whee...

-

Bottom price Surface Grinding - Aluminum Oxide...