High Quality for Abrasive Cut Off Wheel - Hypodermic Needle Grinding Wheels – YUXINGAN Detail:

Product Introduction

This product is widely used in stainless steel, copper, aluminum and other metals and glass, furniture, ceramics, marble and other non-metal fine polishing.

Competitive Advantages

1. Experienced manufacturer can guarantee the quality and best Price;

2. Satisfactory pre-sale service& after-sale services;

3. Discount for long cooperated partner , and so on.

Abrasives And Usages

| ABRASIVE | USAGE |

| Brown Aluminum Oxide | It is suitable for grinding medium and high tensile strength metal . |

| White Aluminum Oxide | It is used for grinding harder material and metals sensitive to heat such as chilled steel, high carbon steel, ordinary high speed steel, alloy steel ,It is mainly suitable for the grinding and forming grinding of instrument, cutting tools, mould, gears, threads ,thin-wall parts, etc. |

| Pink Aluminum Oxide | It is suitable for the grinding of chilled steel, cutting tools and workpieces of alloy steel as well as the precision grinding of measuring tools and parts of instruments and appratus, etc. |

| Monocrystalline Aluminum Oxide | It is suitable for the grinding of stainless steel , high vanadium-high speed steel and the workpieces in high toughness and being easily-deformed and burnt. |

| Mixture of A and WA | It is suitable for the grinding of nodular cast iron crankshaft, cam shafts and other workpieces. |

| Green silicon carbide | It is suitable for the grinding of cutting tools and workpieeces of hard alloy, and non-metal materials, etc. |

| Black silicon carbide | It is suitable for the grinding of non-ferrous and non-metal materials. |

Shapes Of Our Product

Straight Wheels; Cylinder Wheels; Tapered Wheels; Recessed Wheels; Cup Wheels; Crankshaft Wheel; Internal Grinding Wheels; oilstone; Cutting-off dish; Centerless Wheels; and so on.

Type Code

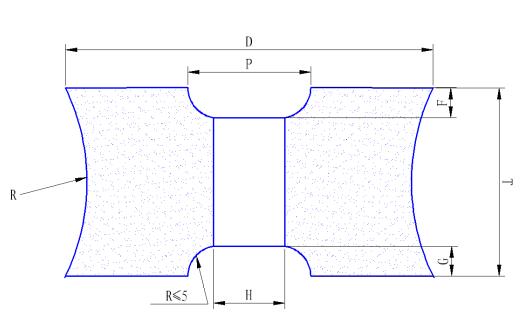

Type Code: 7-J

|

OD |

T |

H |

P |

F=G |

R |

Grit |

Grain |

Hardness |

Structure |

Speed |

|

400mm |

150mm |

100mm |

170mm |

25mm |

150mm |

A WA AA 38A 25A PA SA |

F46 F54 F60 F80 F100 |

K L M N P Q |

5 6 7 8 9 10 |

33m/s 35m/s 40m/s 45m/s 50m/s 60m/s |

|

450mm |

200mm |

150mm |

225mm |

25mm |

200mm |

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is superior, Services is supreme, Standing is first", and will sincerely create and share success with all customers for High Quality for Abrasive Cut Off Wheel - Hypodermic Needle Grinding Wheels – YUXINGAN, The product will supply to all over the world, such as: Seattle, Bangladesh, Salt Lake City, We have been fully aware of our customer's needs. We deliver high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

-

Hot sale Cement Truck - Fast delivery China Pu...

-

Factory Free sample China Polishing Wheel - Ab...

-

Professional China Metal Grinding Disc - Polis...

-

Well-designed Needle Grinding Stone - Abrasive...

-

Online Exporter Resin Grinding Wheels - Alumin...

-

Concrete pump - Fast delivery China Putzmeiste...