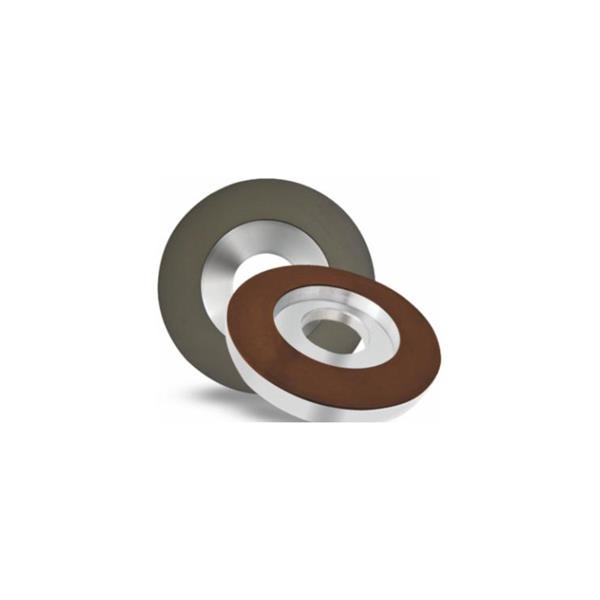

Low MOQ for Roll Grinding Wheel - Grinding Wheel Used On Engine Valve End-Face – YUXINGAN Detail:

Product Introduction

The end face grinding wheel is mainly used for grinding the end face of bearing ring and piston ring and soon.It’s resin oid grinding wheel.It has chr acteristics of high pressure resistance, more congress ive,high effeciency,high precision etc.

Resin bond is the most common choice for diamond and cubic boron nitride superabrasive wheels. Form a bonding structure to keep the grinding wheel cutting sharp, with high surface finish, high grinding efficiency, and low heat generation. The most important thing is that it is very cost-effective. It is more competitive than ceramic bond and metal bond. Therefore, it is widely used in the grinding industry. Diamond has a better effect on cemented carbide, and CBN has a better effect on HSS.

In addition, some customers also use resin bond diamond grinding wheels as dressing tools. Because CBN grinding wheels are very hard, ordinary grinding wheels are not suitable for dressing

Typical Grinding Wheel

| Typical grinding wheel: |

| 36-500×65×19A/F60P6B35m/s |

| 36-600×65×19A/F60P6B35m/s |

| 36-750×65×50SA/F80L7B35m/ |

Note: We can design and produce any specification grinding wheel as customer’s requirement. If you have any questions, do not hesitate to contact us. Customer’s requirements always meet with our careful attention.

Shapes Of Our Product

Straight Wheels; Cylinder Wheels; Tapered Wheels; Recessed Wheels; Cup Wheels; Crankshaft Wheel; Internal Grinding Wheels; oilstone; Cutting-off dish; Centerless Wheels; and so on.

Product detail pictures:

Related Product Guide:

Our intention is usually to satisfy our buyers by offering golden provider, great rate and good quality for Low MOQ for Roll Grinding Wheel - Grinding Wheel Used On Engine Valve End-Face – YUXINGAN, The product will supply to all over the world, such as: Ethiopia, Marseille, Casablanca, Our products and solutions are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, be sure to contact us today. We will sincerely create and share success with all clients.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.

-

Manufacturing Companies for Polishing Wheel Too...

-

Leading Manufacturer for 7inch Cup Wheels - Wh...

-

100% Original Cutting Tools - Flat Roll Resin ...

-

Short Lead Time for Phenolic Resin Grinding Whe...

-

New Fashion Design for Polishing Discs - Flexi...

-

New Arrival China Cutting Disc Grinding Wheel -...