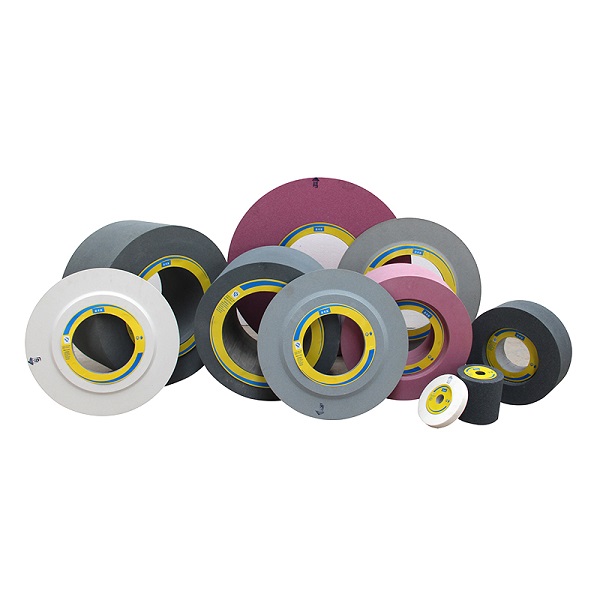

Manufacturer of Grinding Cup Wheel - White Aluminum Oxide Bearing Grinding Wheels – YUXINGAN Detail:

Application Field

Abrasive tools cover the entire manufacturing process of the bearing, such as bearing ring and roller cross-section grinding, centerless grinding, inner and outer ring channel grinding, bearing internal grinding, etc.

The grinding wheel used to cut the raceway of the bearing adopts high-quality mixed abrasives and special-performance binders to form fine pulverization characteristics in the grinding abrasives and maintain its cutting edge performance. At the same time, the bonding agent has good bending strength and small mold elasticity, the modified shape is easy to maintain, and the grinding accuracy of the raceway can be guaranteed.

Features

The grinding wheel has the characteristics of good shape retention, sharp grinding, high grinding accuracy, and high durability; the groove shape is maintained well, reaching or close to the level of similar foreign products; durability: dressing frequency ≥ 10 pieces/time; processing efficiency: 1 piece /Min; Used in the grinding of bearing inner ring raceway and inner ring raceway.

Type Code

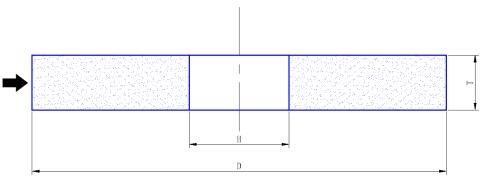

Type Code: 1

Whatever their geometric dimension, stable work, extreme high grinding precision, or their high grinding efficiency, noise, etc., the Bearing grinding wheels can all meet the increasing strict manufacturing requirements.

|

OD |

T |

H |

Grit |

Grain |

Hardness |

Structure |

Speed |

|

|

500mm 600mm |

14mm-50mm |

305mm |

A WA AA 38A |

F46 F60 F80 F100 F120 |

L M N P Q |

5 6 7 8 9 10 |

35m/s 40m/s 45m/s 50m/s 60m/s |

|

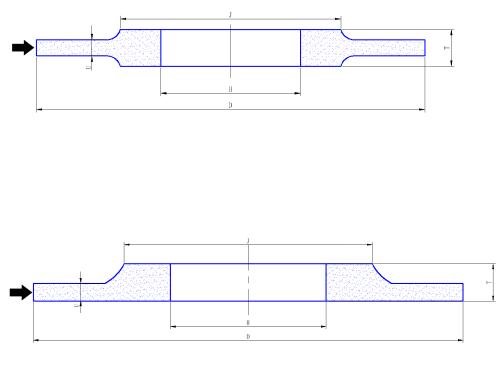

Type Code: 38; 39

The abrasive tools cover the whole manufacturing process of bearings, such as bearing ring and rollers section grinding, centerless grinding, inner-outer races channel grinding, internal grinding of the bearings, etc. Xinfa brand abrasive tools bring advanced grinding way for the whole bearing processing industry. Whatever their geometric dimension, stable work, extreme high grinding precision, or their high grinding efficiency, noise, etc., the wheels can all meet the increasing strict manufacturing requirements.

|

OD |

T |

H |

Grit |

Grain |

Hardness |

Structure |

Speed |

|

500mm 600mm |

14mm-50mm |

305mm |

A WA AA 38A |

F46 F60 F80 F100 F120 |

L M N P Q |

5 6 7 8 9 10 |

35m/s 40m/s 45m/s 50m/s 60m/s |

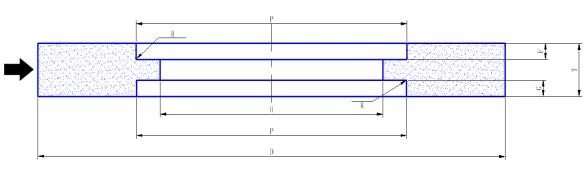

Type Code: 7

|

OD |

T |

H |

J |

U |

Grit |

Grain |

Hardness |

Structure |

Speed |

|

500mm |

16mm |

305mm |

350mm |

6mm 8mm |

A WA AA 38A SA |

F60 F80 F100 F120 |

K L M N P Q |

5 6 7 8 9 10 |

35m/s 40m/s 45m/s 50m/s 60m/s |

|

20mm |

10mm 13mm |

||||||||

|

600mm |

20mm |

8mm 10mm |

|||||||

|

25mm |

13mm 16mm |

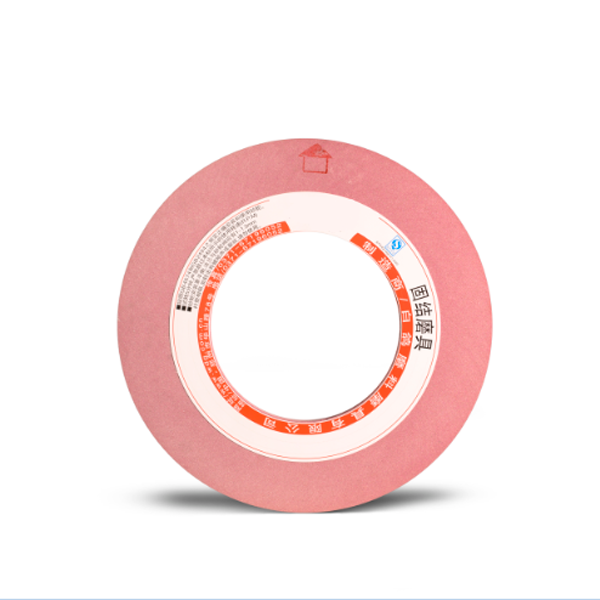

Product detail pictures:

Related Product Guide:

The consumer fulfillment is our primary goal. We uphold a consistent level of professionalism, top quality, credibility and service for Manufacturer of Grinding Cup Wheel - White Aluminum Oxide Bearing Grinding Wheels – YUXINGAN, The product will supply to all over the world, such as: Estonia, Myanmar, Sao Paulo, Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don't hesitate to contact us. We will do our best to meet your needs.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.

-

China Isuzu Vc61 6*4 460HP 10 Cubic Concrete Tr...

-

Big Discount Resin Cup Wheel - White Aluminum ...

-

OEM Manufacturer Abrasive Flap - Rubber Contro...

-

Hot-selling Cutting Tool - Flat Roll Resin Bon...

-

Cheap PriceList for Abrasive Technology - Rubb...

-

Material Hoist - Fast delivery China Putzmeist...