Manufacturing Companies for Polishing Wheel Tool - Centreless Grinding Wheel For Grinding Piston Rods – YUXINGAN Detail:

Application

Surface finishing

Slitting and parting

Descaling, deburring

Stock removal finishing of flat as well as cylindrical surface

Grinding of tools and cutters and re sharpening of the same.

Applicable Fields

Conventionally grinding is characterized as low material removal process capable of providing both high accuracy and high finish. However, advent of advanced grinding machines and grinding wheels has elevated the status of grinding to abrasive machining where high accuracy and surface finishas well as high material removal rate can be achieved even on an unhardened material.

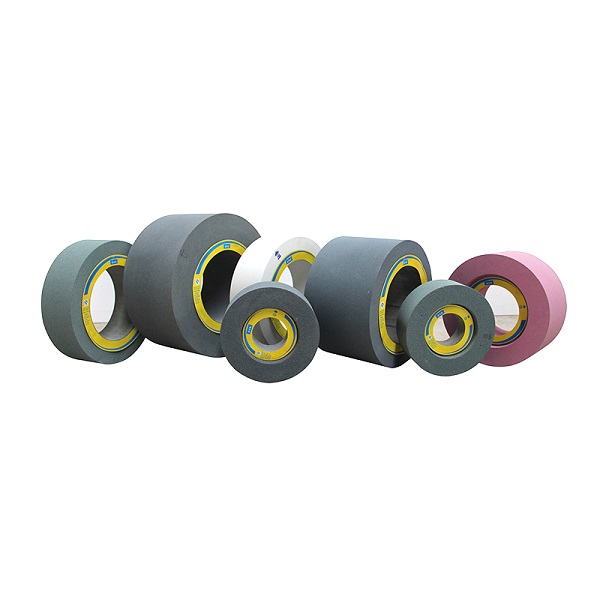

The wheels are mainly used for grinding mass slender axles,short axles without center hole,specific taper pins,bearing, many type shafts etc.

Features

Conventionally grinding is characterized as low material removal process capable of providing both high accuracy and high finish. However, advent of advanced grinding machines and grinding wheels has elevated the status of grinding to abrasive machining where high accuracy and surface finishas well as high material removal rate can be achieved even on an unhardened material.

Using special bonding agent and unique manufacturing technology, the grinding wheel has sharp grinding, low grinding heat and high grinding efficiency. Good shape retention of the workpiece, no burns. The dimensional accuracy of the grinding wheel is consistent, the flatness is less than 0.1 mm, and the coaxiality is less than 0.1 mm, which is easy to combine and use. It is used in the grinding of different precisions of rods in the bearing industry and the automotive industry.

Surface finishing; slitting and parting; descaling, deburring; stock removal finishing of flat as well as cylindrical surface; grinding of tools and cutters and re sharpening of the same.

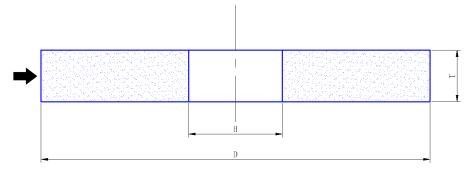

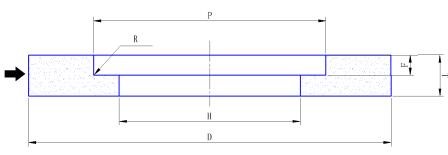

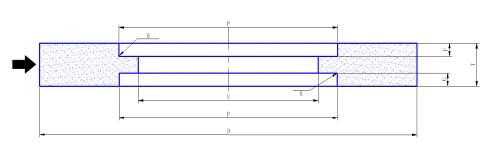

Type Code

Type Code: 1

Type Code: 5

Type Code: 7

|

OD |

T |

H |

P |

F |

R |

Grit |

Grain |

Hardness |

Structure |

Speed |

|

300mm |

100mm-125mm |

127mm 152.4mm |

190mm |

10mm 16mm 20mm 25mm |

5mm 8mm |

A WA AA 38A 25A PA SA GC C |

F36 F46 F54 F60 F80 F100 F120 |

K L M N P Q |

5 6 7 8 9 10 |

33m/s 35m/s 40m/s 45m/s 50m/s 60m/s |

|

350mm |

100mm-150mm |

200mm |

||||||||

|

400mm |

100mm-250mm |

203mm 203.2mm 225mm 254mm |

265mm 280mm |

|||||||

|

450mm |

150mm-200mm |

|||||||||

|

500mm |

100mm-300mm |

304.8mm 305mm |

375mm 400mm |

|||||||

|

600mm |

150mm-300mm |

|||||||||

|

750mm |

400mm |

435mm |

Product detail pictures:

Related Product Guide:

Our primary intention should be to offer our clientele a serious and responsible enterprise relationship, delivering personalized attention to all of them for Manufacturing Companies for Polishing Wheel Tool - Centreless Grinding Wheel For Grinding Piston Rods – YUXINGAN, The product will supply to all over the world, such as: Morocco, Pretoria, United Arab emirates, We supply skilled service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound items with good logistics service and economical cost. Depending on this, our products and solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.

-

18 Years Factory Ceramic Grinding Wheel - Hypo...

-

Cheap PriceList for Angle Grinder Cutoff Wheel ...

-

Top Quality Grinding Wheel For Bevel Gear - Cy...

-

Factory selling Abrasive Flap Disc - Flexible ...

-

Good Quality Grinding/Flap Disc For Wood/Metal ...

-

Super Lowest Price Building Lift - PT80 Series...