OEM Manufacturer Abrasive Flap - Rubber Control & Centreless – YUXINGAN Detail:

Product Introduction

Good shape maintenance, suitable for the processing ofhigh-precision tools; The amount of feed can reach 4-7mm; Machined work pieces with good surface finish; Very low spindle load; High-quality Diamond Segment Made from High-gradeDiamond bySpecial and Advanced Technics.

Application

For rubber roller grinding or grooving process with full range of hardness by selection the suitable grit and specification.

Product Description

1. We provide alloy grinding wheels and grooving wheels of various sizes for grinding and grooving of rubber rollers. Please consult us for the best wheel for your application.

2. Select the appropriate particle size according to the situation of Cots with different hardness, which is suitable for high-quality grinding and grooving of cots.

|

Grit Choice of Grinding Wheel |

|

|

Grit |

Rubber and Polyurethane |

|

32 |

< 50 Shore A (Soft) |

|

35 |

|

|

38 |

|

|

40 |

|

|

50 |

|

|

60 |

60 – 70 Shore A (Medium) |

|

70 |

|

|

80 |

|

|

90 |

> 80 Shore A (Hard) |

|

100 |

|

|

125 |

|

|

132 |

|

Advantage

Sturdy and reliable, this multi-bore Bench Grinding Wheel is ideal for sharpening a variety of cutting tools, giving a fine grain surface finish where you need it most.

Multi-bore – fits most machines

Fine grain sharpening

Good surface finish

Carbide Grinding Wheels

Used for Best performance and economy of carbide tool maintenance, Manufactured in vitrified bond.

Available in:

• Green Carbide (GC)

• Black Silicon Carbide (C)

• Mixture – Black Green Silicon Carbide (GC/C)

Recommendations:

• Grit 46 (Coarse) – Rough Grinding

• Grit 60/80 (Medium – General Purpose

• Grit 80/100/120 (fine) – Sharpening the Cutting edge

Types:

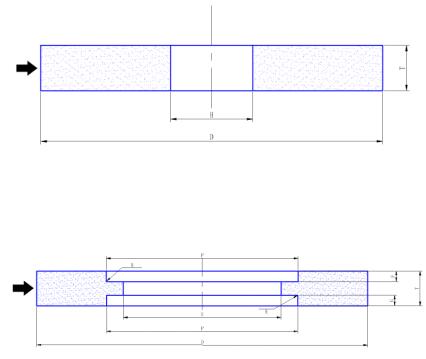

• Straight Wheels (Type 1)

Type Code

Type Code: 1; 7

|

OD |

T |

H |

Grit |

Grain |

Hardness |

Structure |

Speed |

|

200mm |

100mm |

75mm |

A WA AA 38A |

F80 F100 F120 |

K L M N P Q |

5 6 7 8 9 10 |

33m/s 35m/s 40m/s 45m/s 50m/s 60m/s |

|

250mm |

125mm |

127mm |

|||||

|

300mm |

150mm-350mm |

||||||

|

350mm |

125mm-250mm |

127mm |

|||||

|

400mm |

100mm-380mm |

127mm 203mm |

|||||

|

500mm |

100mm-200mm |

305mm |

Product detail pictures:

Related Product Guide:

Persisting in "High high quality, Prompt Delivery, Aggressive Price", we've established long-term cooperation with clients from the two overseas and domestically and get new and old clients' superior comments for OEM Manufacturer Abrasive Flap - Rubber Control & Centreless – YUXINGAN, The product will supply to all over the world, such as: Juventus, Mauritius, Jamaica, If you are for any reason unsure which product to select, do not hesitate to contact us and we will be delighted to advise and assist you. This way we will be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We are looking for more and more customers to create the glorious future.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

-

Trending Products Resin Bond Disc - Metal And ...

-

10t Tower Crane - 58m SITRAK Concrete pump tru...

-

Truck pump - Fast delivery China Putzmeister 3...

-

Super Lowest Price Abrasive Disc For Rubber - ...

-

Well-designed Needle Grinding Stone - Abrasive...

-

OEM/ODM China Manufacture Cutting Disc - Metal...