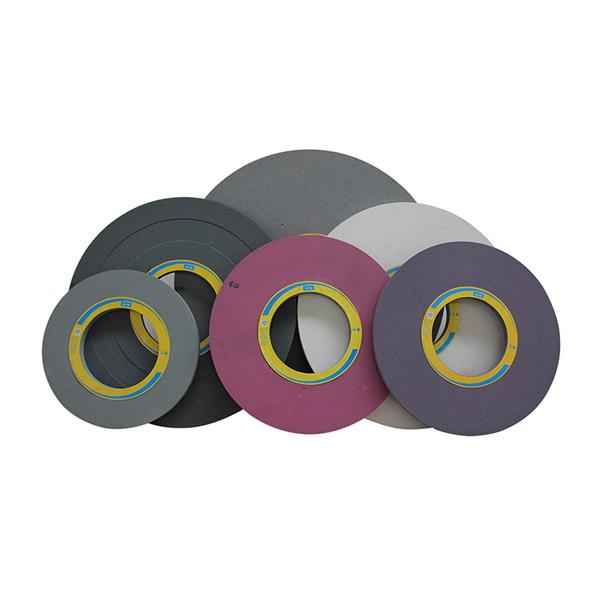

OEM/ODM Manufacturer Grinder Cutting Wheel - Crankshaft Grinding Wheel Vitrified Bonded Grinding Wheel – YUXINGAN Detail:

Scope Of Production

Specification: V-P-750×75×305 – PA/WA -F60-N-60m/s

Specification: V-P-900×35×305 – PA/WA -F60-M-60m/s

Specification: V-P-1065×34×305-PA/WA-F60-M-60m/s

Applicable Fields

Crankshaft grinding wheel is mainly used for automobile, ship, tractor, motorcycle engine and mining machinery. Diesel engine and other crankshaft, camshaft grinding process. Grinding all kinds of crankshafts and connecting rods.

Characteristics Of Grinding Wheel

The static balance of the series of grinding wheel in our company is superior to the national standard 30~50%, and it has good selfsharpness and good maintenance of fillet, long life.The static balance of the set of grinding shaft and camshaft grinding wheel are 50%better then the national standard. The thickness deviation of the grinding wheel is less than 0.2mm and the parallel ity is less than 0.1mm. Excellent geometric accuracy; Good grinding performance; Excellent hardness stability; Excellent R-angle holding and less chances of burn;

The wheels are mainly used for grinding all kinds of crankshafts and camshafts of auto,tractor motorcycle, ship engine as well as transport machinery etc. Our wheels have uniform Structure and hardness. out of balance performance, and cost performance etc.

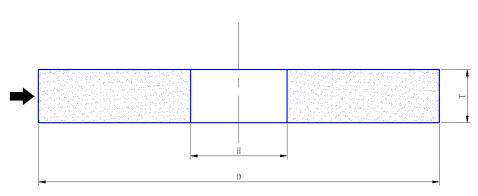

Type Code

|

OD |

T |

H |

Grit |

Grain |

Hardness |

Structure |

Speed |

|

500mm |

16mm 18mm 19mm 20mm 22mm 25mm 32mm 38mm 40mm 50mm 63mm 90mm 120mm |

127mm 203mm 203.2mm 304.8mm 305mm |

A WA AA 38A 25A PA SA GC C |

F36 F46 F54 F60 F80 F100 F120 |

K L M N P Q |

5 6 7 8 9 10 |

33m/s 35m/s 40m/s 45m/s 50m/s 60m/s |

|

600mm |

|||||||

|

610mm |

|||||||

|

635mm |

|||||||

|

660mm |

|||||||

|

700mm |

|||||||

|

710mm |

|||||||

|

750mm |

|||||||

|

760mm |

|||||||

|

810mm |

|||||||

|

900mm |

|||||||

|

1065mm |

|||||||

|

1100mm |

Resin Bond Wheels

Resion bond is usually made with heat-cured resin mainly composed of phenolic resib Resin bond wheel has excellent grinding ability, surface finish and minimal chipping. It is widely applied for difficult- to-machine materials such as cemented carbide, ceramics, glass,and silicon as well as ferroous materials such as high-speed steels and sintered ferrous metals.

Vitrified Bond Wheels

Vitrified bond is a vitreous binding material and generally contains pores inside while other materials contain no pores. Therefore vitrified bond wheels have excellent grinding ability and are superior in forming.

Product detail pictures:

Related Product Guide:

To become the stage of realizing dreams of our employees! To build a happier, more united and extra professional workforce! To reach a mutual advantage of our prospects, suppliers, the society and ourselves for OEM/ODM Manufacturer Grinder Cutting Wheel - Crankshaft Grinding Wheel Vitrified Bonded Grinding Wheel – YUXINGAN, The product will supply to all over the world, such as: Greece, Florence, Mozambique, Now we have a dedicated and aggressive sales team, and many branches, catering to our main customers. We have been looking for long-term business partnerships, and ensure our suppliers that they will undoubtedly benefit in both short and long run.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

-

Best Price for Polish Tools - Flat Roll Resin ...

-

China OEM Cutting Wheel Price - Corundum Worm ...

-

OEM Supply Abrasive - Rubber Control & Cen...

-

Wholesale Price End Grinding Disc - Metal And ...

-

High Quality Concrete Pump Truck - 70m SITRAK ...

-

China Supplier Mini Quick Change Cutting Disc -...