Popular Design for Tungsten Carbide Grinding Wheel - Centreless Grinding Wheel For Grinding Piston Rods – YUXINGAN Detail:

Application

Surface finishing

Slitting and parting

Descaling, deburring

Stock removal finishing of flat as well as cylindrical surface

Grinding of tools and cutters and re sharpening of the same.

Applicable Fields

Conventionally grinding is characterized as low material removal process capable of providing both high accuracy and high finish. However, advent of advanced grinding machines and grinding wheels has elevated the status of grinding to abrasive machining where high accuracy and surface finishas well as high material removal rate can be achieved even on an unhardened material.

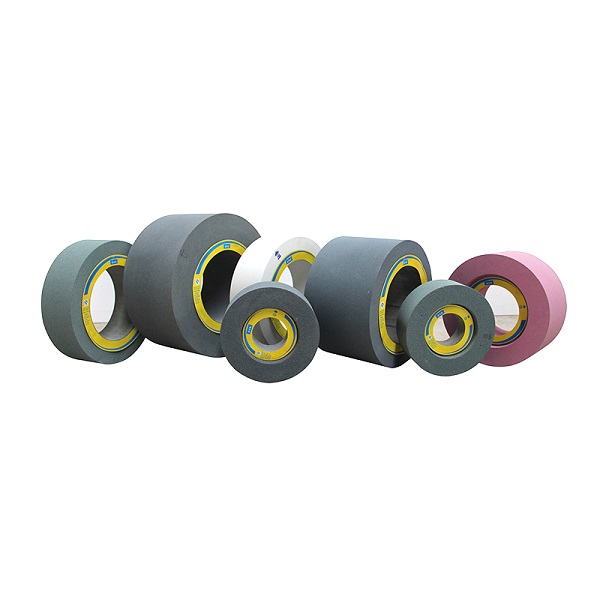

The wheels are mainly used for grinding mass slender axles,short axles without center hole,specific taper pins,bearing, many type shafts etc.

Features

Conventionally grinding is characterized as low material removal process capable of providing both high accuracy and high finish. However, advent of advanced grinding machines and grinding wheels has elevated the status of grinding to abrasive machining where high accuracy and surface finishas well as high material removal rate can be achieved even on an unhardened material.

Using special bonding agent and unique manufacturing technology, the grinding wheel has sharp grinding, low grinding heat and high grinding efficiency. Good shape retention of the workpiece, no burns. The dimensional accuracy of the grinding wheel is consistent, the flatness is less than 0.1 mm, and the coaxiality is less than 0.1 mm, which is easy to combine and use. It is used in the grinding of different precisions of rods in the bearing industry and the automotive industry.

Surface finishing; slitting and parting; descaling, deburring; stock removal finishing of flat as well as cylindrical surface; grinding of tools and cutters and re sharpening of the same.

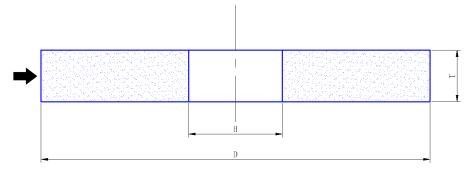

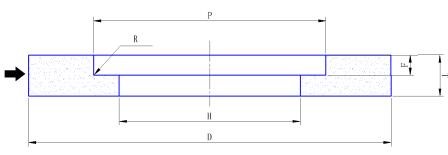

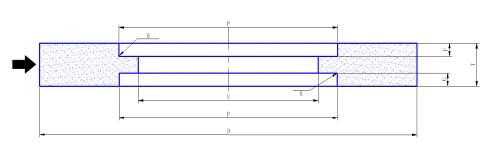

Type Code

Type Code: 1

Type Code: 5

Type Code: 7

|

OD |

T |

H |

P |

F |

R |

Grit |

Grain |

Hardness |

Structure |

Speed |

|

300mm |

100mm-125mm |

127mm 152.4mm |

190mm |

10mm 16mm 20mm 25mm |

5mm 8mm |

A WA AA 38A 25A PA SA GC C |

F36 F46 F54 F60 F80 F100 F120 |

K L M N P Q |

5 6 7 8 9 10 |

33m/s 35m/s 40m/s 45m/s 50m/s 60m/s |

|

350mm |

100mm-150mm |

200mm |

||||||||

|

400mm |

100mm-250mm |

203mm 203.2mm 225mm 254mm |

265mm 280mm |

|||||||

|

450mm |

150mm-200mm |

|||||||||

|

500mm |

100mm-300mm |

304.8mm 305mm |

375mm 400mm |

|||||||

|

600mm |

150mm-300mm |

|||||||||

|

750mm |

400mm |

435mm |

Product detail pictures:

Related Product Guide:

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for Popular Design for Tungsten Carbide Grinding Wheel - Centreless Grinding Wheel For Grinding Piston Rods – YUXINGAN, The product will supply to all over the world, such as: European, Rotterdam, Turin, We pay high attention to customer service, and cherish every customer. We have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

We have been looking for a professional and responsible supplier, and now we find it.

-

Cheapest Price Polish Tools Wheel - Cylindrica...

-

Factory directly supply Flap Discs For Metals -...

-

2022 wholesale price Flat-Top Tower Cranes - Q...

-

Wholesale Price China 350mm Cutting Disc - Pol...

-

Hot sale Flat Top Crane - 52m Concrete pump tr...

-

Best quality Grinding Discs - Super-thin Cutti...